Thermal Silicone Pad 3.2W, Ultra High Conductivity Gap Filler For AI Servers, GPU Cooling, Inverter

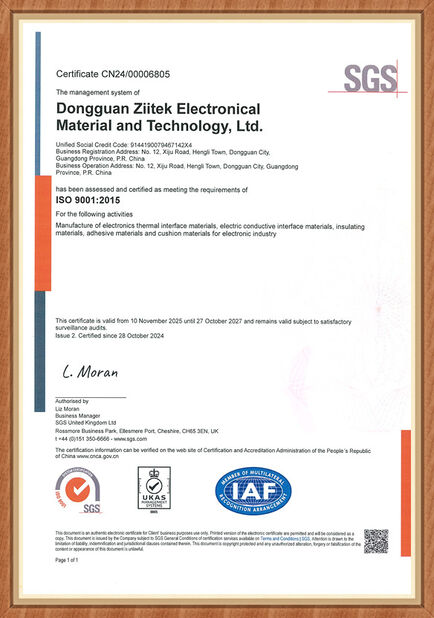

Company Profile

Dongguan Ziitek Electronic Material Technology Co., Ltd. was established in 2006. Is a high-tech enterprise specializing in the research, development, production and sales of thermal interface materials. We mainly produce: heat-conducting joint filler, low melting point thermal interface materials, heat-conducting insulator, heat-conducting adhesive tape, heat-conducting interface pad and heat-conducting grease, heat-conducting plastic, silicone rubber, silicone rubber foam, etc. We adhere to the business philosophy of "survival by quality, development by quality", and continue to provide the most efficient and best service for new and old customers with excellent quality in the spirit of rigor, pragmatism and innovation.

The TIF®100-32-05U Series is an ultra soft thermal interface material designed specifically to protect precision components that are extremely sensitive to mechanical stress. This product combines high thermal conductivity with extreme gel grade flexibility to achieve a perfect fit with low stress.It is suitable for solving problems such as large tolerances,uneven surfaces, and susceptibility of precision components to mechanical damage in high-precision assembly.

Features:

> High thermal conductivity: 3.2W/mK

> Ultra soft and highly compliant

> Self-adhesive without the need for additional surface adhesives

> Good insulation performance

Applications

> AI Servers, Inverters, Telecom Devices

> Power tools

> Network communication products

> Electric vehicle batteries Computer CPU/GPU Cooling

> New energy vehicle power systems

> Signal communication

> New energy vehicle

> Motherboard chip

> Radiator

| Typical Properties of TIF®100-32-05U Series |

| Property |

Value |

Test method |

| Color |

Blue |

Visual |

| Construction & Compostion |

Ceramic filled silicone elastomer |

****** |

| Density(g/cm³) |

3.0 |

ASTM D792 |

| Thickness Range(inch/mm) |

0.010~0.020

(0.25~0.50)

|

0.030~0.200 (0.75~5.0) |

ASTM D374 |

| Hardness |

65 Shore 00 |

27 Shore 00 |

ASTM 2240 |

| Recommended Operating Temperature |

-40 to 200℃ |

****** |

| Breakdown Voltage(V/mm) |

≥5500 |

ASTM D149 |

| Dielectric Constant |

3.5 MHz |

ASTM D150 |

| Volume Resistivity |

>1.0X1012 Ohm-meter |

ASTM D257 |

| Flame rating |

V-0 |

UL 94 (E331100) |

| Thermal conductivity |

3.2 W/m-K |

ASTM D5470 |

|

3.2 W/m-K

|

ISO22007 |

Product Specifications

Standard Thickness: 0.010"(0.25 mm)-0.20" (5.00 mm) with increments of 0.010 inch (0.25 mm).

Standard Size: 16"×16" (406 mm ×406 mm)

Component Codes:

Reinforcement Fabric: FG (Fiberglass).

Coating Options: NS1 (Non-adhesive treatment),

DC1 (Single-sided hardening).

Adhesive Options: A1/A2 (Single-sided/Double-sided adhesive).

The TIF® series is available in custom shapes and various forms.

For other thicknesses or more information, please contact us.

Independent R&D team

Q: How do I place an order?

A:1. Click the "Sent messages" button to continue with the process.

2. Fill out the message form by entering a subject line, and message to us.

This message should include any questions you might have about the products as well as your purchase requests.

3. Click the "Send" button when you are finished to complete the process and send your message to us.

4. We will reply you as soon as possible with Email or online.

FAQ

Q: Are you trading company or manufacturer ?

A: We are manufacturer in China.

Q: What's the thermal conductivity test method given on the data sheet ?

A: All the data in the sheet are actual tested.Hot Disk and ASTM D5470 are utilized to test the thermal conductivity.

Q: How to find a right thermal conductivity for my applications

A: It depends on the watts of power source , ability of heat dissipation. Please tell us your detailed applications and the power, so we can recommend most suitable thermal conductive materials.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!