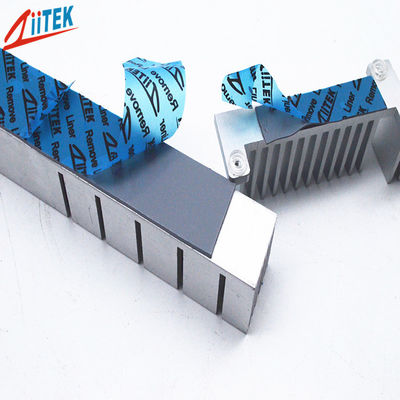

El embalaje de la almohadilla térmica

1.con película de PET o espuma para protección

2. usar papel cartón para separar cada capa

3. cartón de exportación interior y exterior

4. satisfacer las necesidades de los clientes

Tiempo de entrega: cantidad: piezas:5000

Tiempo (días): a negociar

Perfil de la empresa

Dongguan Ziitek Electronic Material Technology Co., Ltd fue establecida en 2006. es una empresa de alta tecnología especializada en la investigación, desarrollo,producción y venta de materiales de interfaz térmicaProducimos principalmente: relleno de juntas conductoras de calor, materiales de interfaz térmica de bajo punto de fusión, aislante conductor de calor, cinta adhesiva conductora de calor,una placa de interfaz conductora de calor y una grasa conductora de calor,, plástico conductor de calor, caucho de silicona, espuma de caucho de silicona, etc. Nos adherimos a la filosofía de negocio de "supervivencia por calidad, desarrollo por calidad",y seguir proporcionando el servicio más eficiente y mejor para los clientes nuevos y viejos con excelente calidad en el espíritu de rigor, pragmatismo e innovación.

Tamaño de la fábrica: 8000 ~ 10.000 metros cuadrados

Países/regiones de fabricación: No.12, calle Xiju, municipio de Hengli, ciudad de Dongguan, provincia de Guangdong, República Popular China

Servicio en línea: 12 horas, respuesta a la consulta en el más rápido.

Horario de trabajo: 8:00 a.m. a 17:30 p.m., de lunes a sábado (UTC+8).

El personal bien entrenado y experimentado responderá a todas sus consultas en inglés, por supuesto.

Cartón de exportación estándar o marcado con la información del cliente o personalizado.

Proporcionar muestras gratuitas

Después del servicio: Incluso nuestros productos han pasado una inspección estricta, si encuentra que las piezas no pueden funcionar bien, por favor muéstrenos la prueba.

Le ayudaremos a lidiar con él y le daremos una solución satisfactoria.

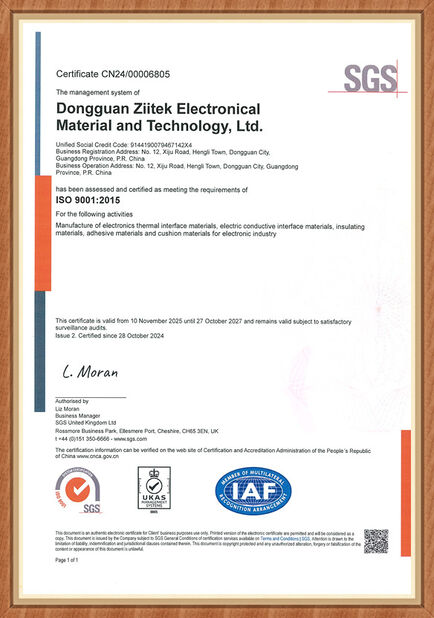

Las certificaciones:

Se trata de la norma ISO 9001:2015

Las condiciones de las pruebas de seguridad de los equipos de ensayo deberán cumplirse en el caso de los equipos de ensayo.2016

Las condiciones de las condiciones de ensayo se determinarán en el anexo I.2017

El número de

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!