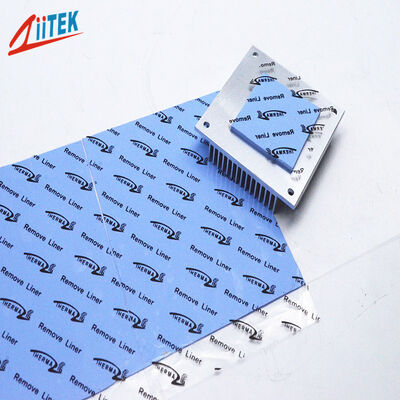

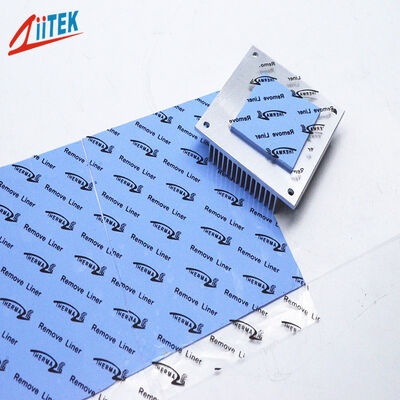

Low compression stress Thermal GAP PAD Materials for Computer CPU/GPU Cooling

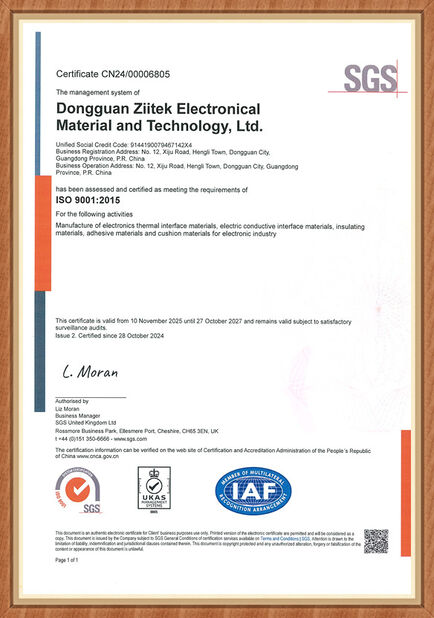

Company Profile

Ziitek Electronic Material and Technology Ltd. is a R&D and production company, we have many production lines and processing technology of thermal conductive materials, owns advanced production equipment and optimized process, can provide various thermal solutions for different applications.

Products description

TIF®500-30-05U Series is an ultra-soft thermal interface material designed specifically to protect precision components that are extremely sensitive to mechanical stress. This product combines high thermal conductivity with exceptional gel-level softness,achieving a perfectly low-stress fit. It is suitable for addressing issues such as large tolerances, uneven surfaces,and the susceptibility of precision components to mechanical damage in high-precision assemblies.

Features:

> High thermal conductivity

> Super soft and highly compliant

> Self-adhesive without the need for additional surface adhesives

> Good insulation performance

Applications:

> Power tools

> Network communication products

> Electric vehicle batteries

> Computer CPU/GPU Cooling

> New energy vehicle power systems

| Typical Properties of TIF®500-30-05U Series |

| Property |

Value |

Test method |

| Color |

Blue |

Visual |

| Construction & Compostion |

Ceramic filled silicone elastomer |

****** |

| Density(g/cm³) |

3.0 |

ASTM D792 |

| Thickness Range(inch/mm) |

0.010~0.020 |

0.030~0.200 |

ASTM D374 |

| (0.25~0.5) |

(0.75~5.0) |

| Hardness |

65 Shore 00 |

27 Shore 00 |

ASTM 2240 |

| Recommended Operating Temperature |

-40 to 200℃ |

****** |

| Breakdown Voltage(V/mm) |

≥5500 |

ASTM D149 |

| Dielectric Constant |

7.0 MHz |

ASTM D150 |

| Volume Resistivity |

>1.0X1012 Ohm-meter |

ASTM D257 |

| Flame rating |

V-0 |

UL 94 (E331100) |

| Thermal conductivity |

3.0 W/m-K |

ASTM D5470 |

| 3.0 W/m-K |

ISO22007 |

Product Specifications

Standard Thickness: 0.010" (0.25 mm)~0.200" (5.00 mm) with increments of 0.010" (0.25 mm)

Standard Size: 16"× 16" (406 mm×406 mm)

Component Codes:

Reinforcement Fabric: FG (Fiberglass).

Coating Options: NS1 (Non-adhesive treatment),

DC1 (Single-sided hardening).

Adhesive Options: A1/A2 (Single-sided/Double-sided adhesive).

The TIF series is available in custom shapes and various forms.

For other thicknesses or more information, please contact us.

Packaging Details & Lead time

The packaging of thermal pad

1.with PET film or foam-for protection

2. use Paper Card To Separate Each Layer

3. export carton inside and outside

4. meet with customers' requirement-customized

Lead Time :Quantity(Pieces):5000

Est. Time(days): To be negotiated

Why Choose us ?

1.Our value message is'' Do it right the First time, total quality control''.

2.Our core competencies is thermal conductive interface materials.

3.Competitive advantage products.

4.Condidentiality agreement Bussiness Secrect Contract.

5.Free sample offer.

6.Quality assurance contract.

FAQ:

Q: Are you trading company or manufacturer ?

A: We are manufacturer in China.

Q: Do you accept custom orders ?

A:Yes , welcome to custom orders. Our custom elements including dimension , shape , color and coated on side or two sides adhesive or coated fiberglass. If you want to place a custom order , pls kindly offer a drawing or leave your custom order information .

Q: What thermal conductivity test method was used to achieve the values given on the data sheets?

A: A test fixture is utilized that meets the specifications outlined in ASTM D5470.

Q: Is GAP PAD offered with an adhesive?

A: Currently, Most of thermal gap pad surface has double side natural inherent tack,Non-stick surface can also be treated according to customer's requirements.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!